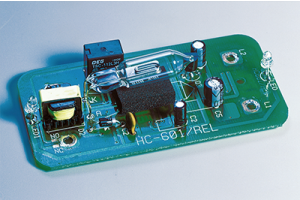

RoHS Compliance

All GCC laser engravers are RoHS-compliant (the European Parliament Directive 2002/ 95/ EC, Restriction of Hazardous Substances) and lead-free (pb free). GCC will continue to concern and provide eco-friendly products to protect the earth for our further generations.

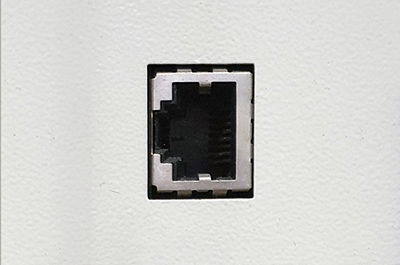

– For USB storage (Max. 32GB capacity, FAT file system)

– For USB storage (Max. 32GB capacity, FAT file system)  – For connecting with the computer

– For connecting with the computer